Quality management

At Kompava, it is important for us that the production process complies with all legislative requirements for the production of nutritional supplements and foods in order to meet the nutritional requirements of intense muscular exertion, especially for athletes.

All of our products meet the requirements of valid food legislation related to EU regulations and decrees of the Ministry of Health and the Ministry of Agriculture. These are, in particular, decrees concerning food additives, flavorings, enzymes, contaminants, pesticide residues, packaging materials, general and specific labeling of allergens. There are also decrees on the use of nutrition and health claims, general hygiene, microbiological criteria and special food additives, as well as forms of vitamins and minerals that can be added to foods, including nutritional supplements.

Effective from January 1st 2016, the products are placed on the market in accordance with the valid legislation, namely amendments to Act no. 355/2007 Coll. on the protection, support and development of public health and on the amendment of certain acts, according to which the current assessment activity of nutritional supplements is replaced, which is conditioned by a decision of the Public Health Office of the Slovak Republic pursuant to § 13 of Act no. 355/2007 Coll. notification obligation of the applicant without issuing a decision of the Public Health Authority of the Slovak Republic.

No doping - the products do not contain any substance from the List of Prohibited Substances of the World Anti-Doping Code. The products do not contain preservatives, synthetic dyes or genetically modified ingredients.

Application of the HACCP critical points system

(Hazard Analysis Critical Control Points)

In the field of production of sports and nutritional supplements, Kompava applies a strict quality management system. The system is in line with the critical point system required for food production. The system analyzes the hazards in the production process, critical points and processes that can affect the quality of products. The system sets out corrective measures to ensure that the health safety of the products is maintained.

Quality control application

The quality control system occurs in the individual steps of the processing) of raw ingredients.

The inspection begins with the initial examination of raw ingredients, continues with the continuous and inter-operational inspection of semi-finished products, and concludes during continuous production and output inspection of final products. If the raw ingredient or semi-finished product does not meet the quality requirements, it is not released for further processing into the final product. The quality of the final product is monitored at random, immediately after production as well as continuously during storage.

Quality control is ensured both in the warehouse containing product raw ingredients, in the production premises and in the warehouse containing finished products. Inspection of production equipment and storage conditions is carried out on a regularly basis.

Product safety and quality assurance

Product safety as well as quality assurance is implemented with a set of activities that ensure the quality and stability of the products.

The set of activities represents the setting of quality requirements for:

- raw ingredients, semi-finished products, final products

- requirements for equipment, technology

- requirements for production and storage facilities

- production and control procedures

- metrology

- staff training, internal and external

- handling complaints and detected nonconforming products

Kompava ensures a system of internal controls and inspections which controls the quality of raw ingredients and final products, as well as evaluates the production process, production environment and compliance with procedures, instructions and record keeping.

Internal control evaluates compliance with all procedures for the purchase of raw ingredients, evaluates the selection of individual suppliers, and checks the safety and suitability of raw ingredient storage.

Food safety policy

Kompava’s upper management is aware of the strategic decision to build, maintain and continuously improve the Quality Management System and has therefore established the following quality management policies:

- In the area of sales, by improving marketing activities, we emphasize customer orientation in order to satisfy and exceed expectations.

- In cooperation with key suppliers, we focus on building long-term relationships based on mutual trust and mindfulness.

- Satisfaction of our customers requires mutual communication and effective cooperation of all departments of the company, including close cooperation with contractual sales representatives.

- Through education and training, we constantly increase the qualifications and competence of all employees and sales representatives of the company, create conditions for their involvement in quality improvement and lead them to make quality a crucial part of their goals.

- We regularly monitor and analyze losses from nonconforming products and develop efforts and conditions for their gradual reduction.

- Internal company quality is ensured by a sophisticated system of input, inter-operational and output control, namely analytical, sensory and microbiological.

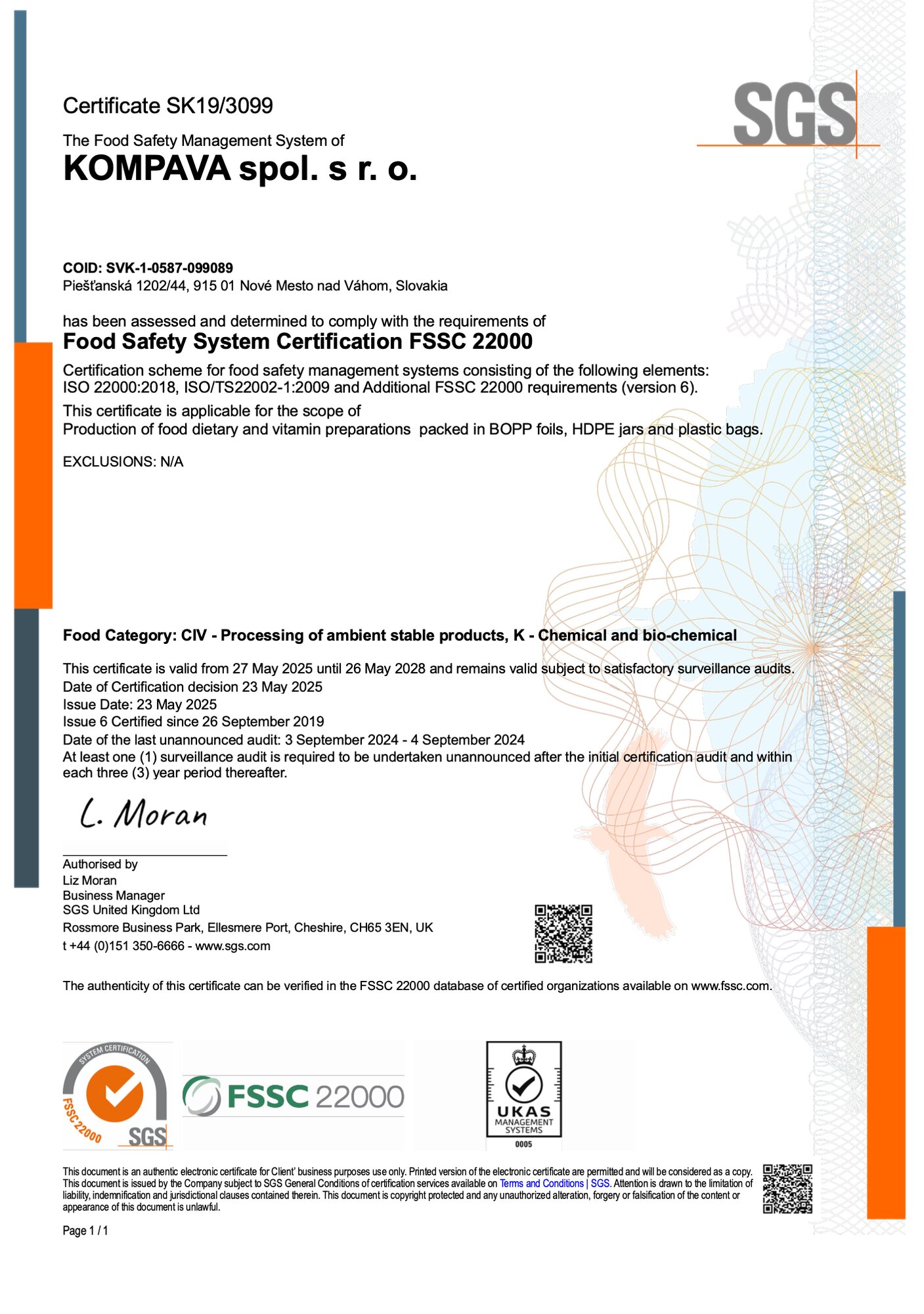

- The company identifies with the requirements of EU legislation. Production and control activities are in accordance with the relevant regulations of the European Parliament and the Council. The company builds and maintains a food safety management system in accordance with the requirements of FSSC 22000.

- The company is committed to meeting the requirements and continuously improving the effectiveness of the quality management system.

Kompava received a certificate in 2020, which confirms that it has contributed to reducing greenhouse gas emissions and is part of the system of recovery and recycling of packaging waste.